There are many different ways to sharpen your whittling knives, and just about every person will develop their own unique way of sharpening their knives over time. This article will walk you through the basics of how to properly sharpen your whittling and wood carving knives so you can maintain a nice and sharp blade that slices right through wood.

Before we start, I need to mention one of the key aspects to a quality wood carving knife, steel hardness. In order to obtain a razor sharp edge that lasts, you will need a knife with a Rockwell Hardness (HRC) between 58 and 62. If it is lower than 58 the edge will dull quickly, but if it is harder than 62 it increases the chance the edge may chip. More information can be found here: https://carvingisfun.com/whittling-knife-hardness/

After following the step by step guide below, you will have a razor sharp knife that can easily slice through wood so you can make clean and easy cuts in wood.

Video Tutorial

Sharpening Tools

When sharpening your knife, you may need to start from a lower grit stone or sand paper, and work your way up to finer grits, finally transitioning to a leather strop to hone your blade to a razor sharp edge.

The 3 most common sharpening tools you can use to sharpen your whittling and wood carving knives are a sharpening stone, sand paper, and a leather strop with polishing compound.

If you are using are using a regular pocket knife that hasn’t been properly shaped and sharpened yet, you will most likely start off using a 400 to 600 grit stone or sandpaper. Then you will work your way up to an 800 to 1000 grit stone or sandpaper to remove the rough scratches from the lower grit tools.

Finally, if you already own a properly sharpened wood carving tool or just got done sharpening your knife with 800 to 1000 grit tools, you will further hone your blade with a leather strop to remove any burs and further enhance the blades edge.

Lets go over each one of these tools so you have a better idea of when you need to use them and where to find them.

– Sharpening Stone

Sharpening stones are going to be the most basic sharpening tool you will use. Many of these tools come with two sides with 400 to 600 grit stone on one side and 800 to 1000 grit on the other.

Using a sharpening stone is primarily for properly shape a brand new general purpose knife that needs to be sharpened for wood carving. If you already have a knife that is razor sharp and regularly gets honed, you wont need to use a stone again unless you heavily damage the blade by dropping or chipping the blade.

There are a lot of sharpening stones on the market, but if you want a nice stone sharpening kit with both 400 grit and 1000 grit sides, look no further than the Sharp Pebble 400/1000 grit Whetstone on Amazon. This stone comes with exactly the right grits you need and comes with a non-slip base. Click here to pick one up for yourself – https://amzn.to/3vbaq4s

– Sand Paper

If you can’t afford a sharpening stone, sandpaper is the next best thing. All you need to do is cut and glue the sandpaper down on to a block of wood or any other hard surface.

Some of my favorite sandpapers to use are wet/dry automotive sand paper as they have a long life and can be used with water as a lubricant and to prevent the metal from sticking to the paper.

I personally like to use the 3M wet/dry automotive sand paper as I can easily pick it up at a nearby hardware store and automotive stores. It can also be picked up on Amazon for a really good price by clicking here – https://amzn.to/3rkMQBn

– Leather Strop with Polishing Compound

Finally, you will want to use a leather strop with polishing compound to further hone and smooth out your blades cutting edge.

This is usually a cured piece of leather that is glued to a hard surface, like a block of wood, and has polishing compound rubbed into the leather. Most experienced wood carvers will already have a knife that has been sharpened properly and won’t have to use anything other than a leather strop to maintain that razor sharp edge.

If you want a quality made leather strop with everything you will need, I highly recommend the BeaverCraft Leather Strop. This is a quality made strop and comes with green polishing compound, which is the only compound you will need. Pick one up for yourself on Amazon by clicking here – https://amzn.to/3O6Ly6t

– How to Use a Leather Strop

Knife Sharpening Methods

Now that you have an idea about what tools you need to sharpen your knives, lets get into how to actually sharpen your knives.

You will eventually develop your own methods, but below are the basics of what you need to do and what to look out for.

How To Hold the Blade Edge

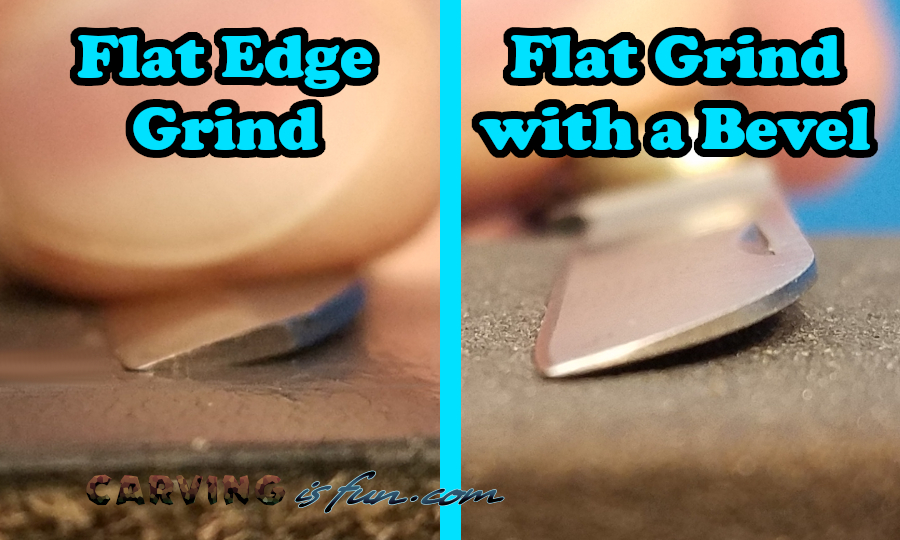

Starting off, you will have to learn how to hold your knife to the sharpening tool. If you have a knife with a flat edge grind, like the Flexcut carving knives, you can easily hold the edge flat to the stone or leather.

However, if you have a knife with a secondary bevel, like a Swiss Army Knife or Old Timer knife, you may have to tilt your blade up a little to ensure the cutting surface is making contact with the sharpening surface.

– How to Sharpen a Flat Edge Blade

When grinding and honing a knife with a flat cutting edge, all you need to do is hold the entirety of the knife edge flat against the sharpening surface.

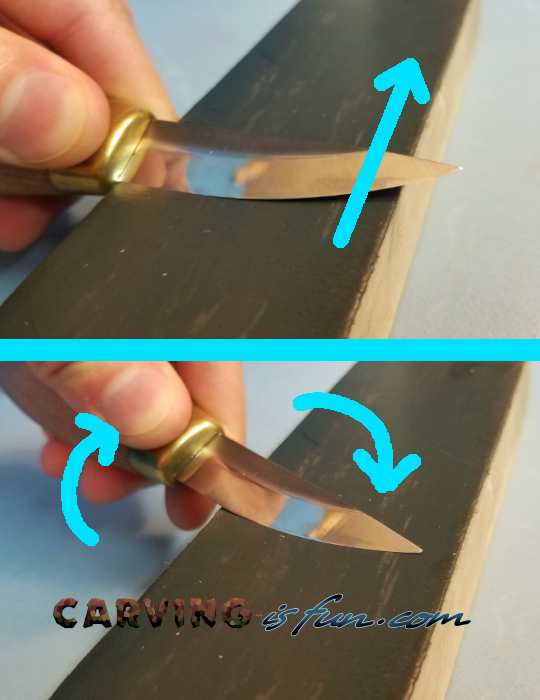

If you are sharpening your knife on sandpaper or a leather strop, you will want to slide your blade along the sharpening surface with the cutting edge trailing. You don’t want to lead with the cutting edge as you can cut directly into the soft leather or sandpaper, damaging your sharpening tool.

On the other hand, if you use a sharpening stone you can actually push and pull the knife edge in either direction if you wish. There have been some studies done where people believe that sharpening your knife with a stone with the cutting edge leading produces fewer burs and results in a better edge for honing.

– How to Sharpen a Curved Blade

If you are sharpening a knife with a curved blade, you will notice that the entire edge of the knife will not make contact with your sharpening surface.

The best way I have found to sharpen these knives is to rotate the blade on the sharpening surface so that the entire cutting edge from handle to tip make contact with the sharpening surface in one pass.

You may have to make twice the number of passes to sharpen when compared to a flat edge knife as you are only sharpening one section of the blade for a short section of a time per pass.

– Common Sharpening Mistakes

When Sharpening, there are some mistakes you don’t want to make or you may end up with an uneven knife edge or just completely damage the sharpness of the blade in general.

One of the worst things you can do when sharpening your wood carving knife is hold your knife at a 45 degree or larger angle. This itself may completely remove your honed and razor sharp cutting edge to the point that you will have to regrind the entire knife edge.

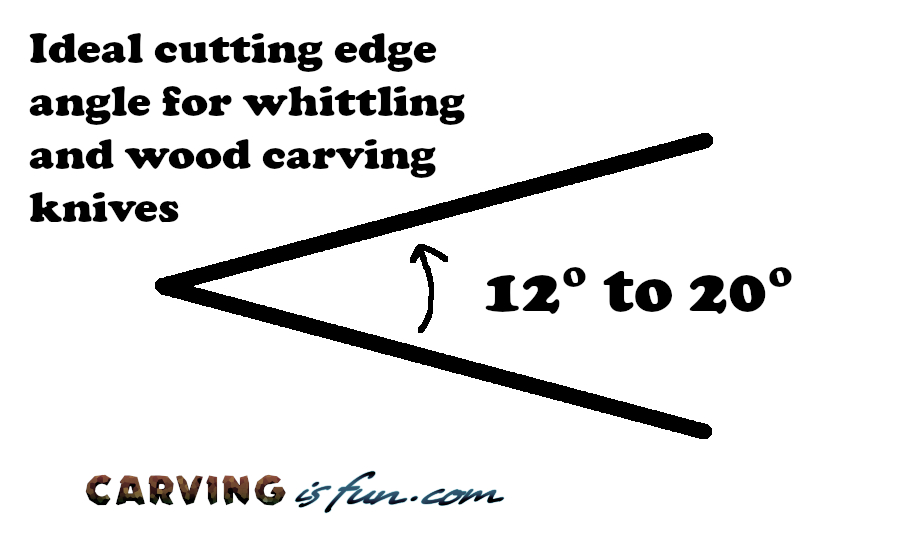

Ideally, you want to hold your knife edge flat to the sharpening surface to maintain the edge you are trying to hone. If you are trying to make a new cutting edge, you will want to target a cutting edge with an angle of 12 to 20 degrees (inclusive).

Another thing some people will do is not hold their knife flat to the sharpening surface, resulting in an uneven grind and inconsistent edge sharpness.

This can be easily remedied by holding a finger along the side of the knife and holding it flat to the edge. This allows you to apply even pressure along the knife edge and promote an even removal of metal.

Best Knife Edge Angles for Wood Carving

Most pocket knives and general purpose knives will have a steep cutting edge angle in excess of 20° and this may make them less than ideal for whittling and wood carving. This is because the steeper cutting edge angle won’t slice through the wood as easily when compared to that of a thinner cutting edge.

When sharpening your whittling and wood carving knives, you will want to target an edge angle between 12 degrees and 20 degrees, inclusive. If the cutting edge is less than 12 degrees, you run the risk of the edge being too narrow and rolling. If the cutting edge angle is too large it will make the blade harder to push through the wood.

Many purpose made whittling and wood carving knives, like Flexcut, OCC Tools, and Helvie, will have this angle already applied to their knives. But some other knives may have to be modified with a sharpening stone for best results.

If you have a wood carving knife with a Scandinavian Grind, like a sloyd knife, an edge grind between 22 degrees to 23 degrees is normal as these knives are designed to be a little more ridged and excel at removing large sections of wood.

More Whittling Tips

If you are new to whittling and wood carving, check out my One Stop Whittling Resource to learn more!